Product Teardown CNC Router MillIE

Overview -

CNC machines are part of the core foundation of our manufacturing infrastructure. For any economy, to embrace its manufacturing capabilities it's workforce should appreciate the foundation and complexities of what it takes to bring products to our homes. I selected this product because the company is based in the US and they try to make things in the US (outsources some components) and it looked pretty good based on the website for our purpose. What is our purpose?: Share the Art, Beauty, and Intricacies of Precision Machine Design. The best way that I saw doing so is by sharing how I see components interconnected to create a beautiful painting and a work of art. Like Leonardo da Vinci we must pay attention to the little things and our foundations. We should grow in love with this overtime just like we do with the people around us. The mnemonic device that I created for the Art of Machine Design is: AAMMOR. A play on words with a very special word in spanish: Love. AAMMOR stands for the following: Analysis, Assembly, Manufacturing, Methodology, Objectivity, and Respect. So Let's dive in with some love for making things.

Observations

Assembly

Manufacturing

Methodology

Objectivity

Respect

Upgrades

Analysis

Eccentric Nuts

Bearings

Linear Motion Guides

Spur Gears

Motor Life & Loading

Opportunitties

Flip the gears

Working Bed Flatness

Little Things

References

Observations

Assembly

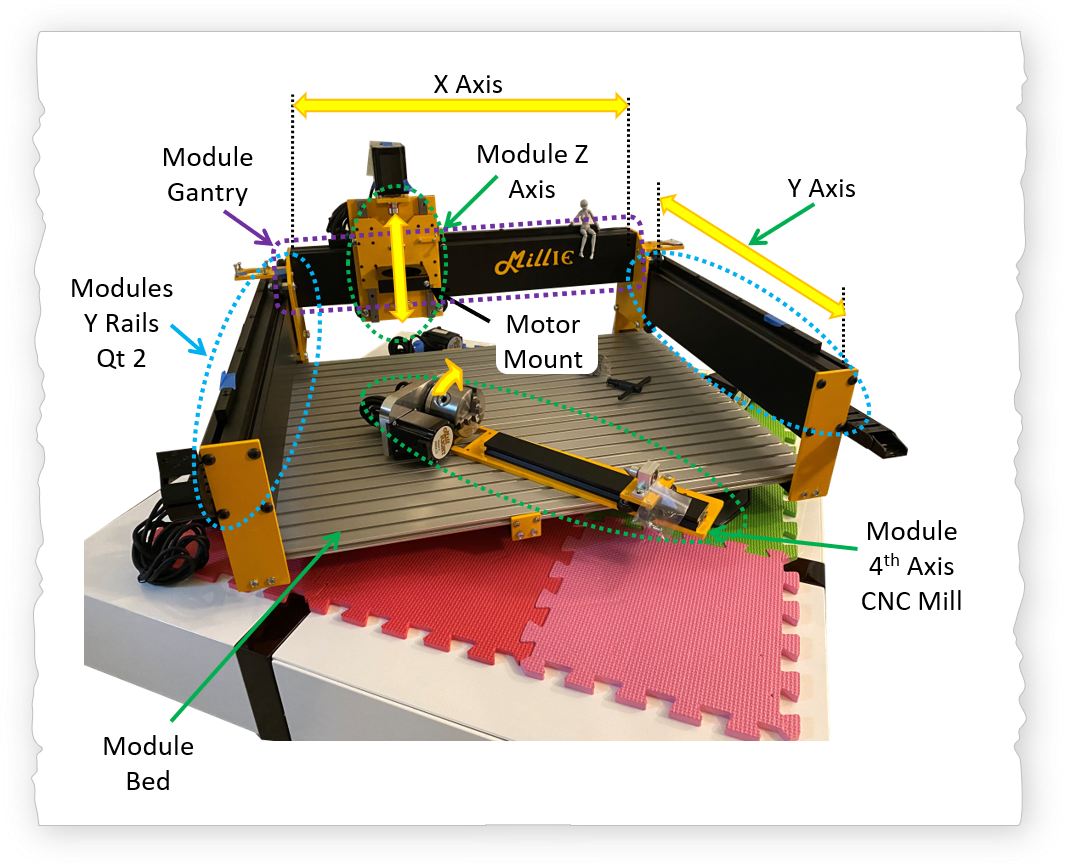

This CNC router or gantry mill (Millie) is one large assembly made up sub-assembly. It is a gantry router. Primaritly designed for cutting: "Mills wood, plastic, foam, carbon fiber, circuit boards, soft metals, and can make occasional light cuts in hard metals." Millie has at least 5 modules: Z axis, X gantry, Y axis, dewalt router (not shown below), and the controls module. There is also an option to have a turning module that will allow the unit to become a little mini lathe.

Manufacturing

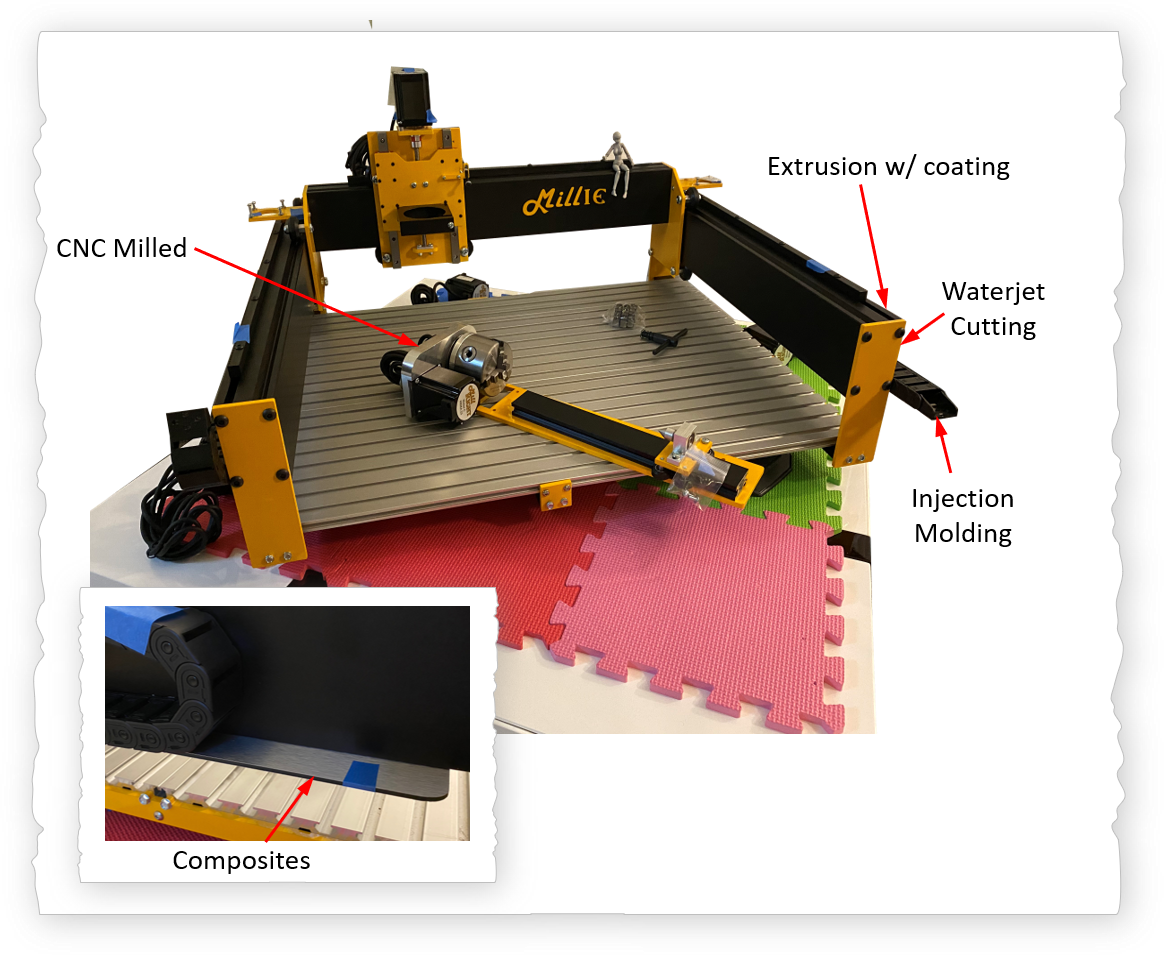

Millie is made up of an array of parts manufactured in at least five ways: 1) Waterjetting: The yellow plates appear to be waterjetted based on the edge surface even after the coating, those features are still visible. 2) Aluminum extrussion: The bed of the router is composed of three extruded plates. The two long channels of the y axis (shown in black) as well as the gantry (shown in black) are also composed of extruded aluminum components. 3) CNC Milling: The forth axis (cnc lathe part) has an aluminum vertical mounting plate that has been CNC milled. 4) Injection molding: The wire guides to minimize wire entanglement are made using injection molding. And 5) Componsites: The plates bellow the wire guides are made of a sandwich of materials. Mmmmmmm, like those little ice cream sandwiches.

Methodology

How we do things matter! In assembly, parts design, manufacturing, drawings, gdnt, etc. the details matter. While assemblying this machine I found that a couple of things that I would do differently based on my experience design for assembly. This section is currently in draft mode.

Modular Assembly, Topic 2, Topic 3

Objectivity

This machine is marketed and designed for hobby routers etc. It is a small company that produces these affordable units. The topics that I am going to discuss and share are intended for precision machines, thus this is only intended for educational purposes only. Summary: Play Nice. Let's keep things in context.

Fabrication equipment like this (Lathe, Mill, etc.) are responsible for getting us a great deal of the technology we have today. The machines that make the circuits boards and the chips that are behind our phones, computers, cars, tv's, etc. are made using parts created on a mill or lathe (there are other too). The semiconductor industry is literally making 20 nm (nanometer) line width in the electronics chips (following Moore's Law). Now we are pushing towards 14 or 16 nm lines: What does this mean?

Let's put that in terms of a football field (360 ft long, or 109.75 meters). If we assume that the entire length of the football field is the width of a human hair (~100 micro meters), then how big is 20nm and 16 nm with resepct to the size of the football field. Again if we assume that a human hair thickness is the entire length of an American Football field then, 20 nm is equivalent to the size of a quarter, and 16 nm is about the size of a dime. That is how tiny those lines are that are powering our digital world! (Next Image: Five year old fingerpaint lines on a football field).

Football Field

Image of American Football Field to width of hair. Put math!

Comparision

20 nm smaller than quarter. 16 nm dime.

Companies

Picture of ASML, KLA Tencor, IBM, companies of semic conductors.

Synergy

Companies that make precision ground telescope optics. Some of those design principles can be readily included into a wood router machine. The challenges are fufilling the multiple aspects for the design pyramid.

Respect: Machine Design Principles

Saint Venant's Principle

Thread engagement, and thread loading. ()

Spur Gear Mounting

Spur Gear on Motor Cantilever effect on motor life.

Upgrades

Occam's Razor: KISS. KEEP IT SUPER SIMPLE. When I assemble a machine and even more when I design a machine, I try to keep it to the minimum number of parts, and optimize the space. While buidling Millie (CNC router), I first assembled the machine how the manufacturer specifies (that is really important). It was only after assemblying the machine and understanding all of the intricacies that I am able to suggest upgrades.

Reduce Parts: Save Cable System & Composite

Upgrade 1: I noticed that since the motors for the y-axis move with the gantry, I can remove one Igus cable system from the motor on the right by simply running the cable thru the gantry. Doing so saves us the use of one composite panel, and one Igus cable system. The width of the machine is as a consequence reduced from 35.0" to under 34.5". Temporarily, I'm running the right y-motor cable on top of the gantry. Eventually I'm going to be running the motor cable thorugh the center of the gantry extrussion. Since, I intend to aslo upgrade the motor holders to reduce the loading on the motors, I'm going to wait before drilling a hole into the side plates of the gantry.

Before

Short 3 min Video

Reduce Space: Move Y-axis cable management

Upgrade 2: In the spirit to getting a more compact design. I tried to consolidate cable management system for the y-axis on the left motor. I did the thought experiement of having an array of these machines for production (Let's say 3 units wide and 5 units high). Thus, I would like to be able to pack these machines one next to the other with minimal space in between. So I looked at putting the y-axis cable management system inside the width of the machine. At the same time I tried to lower the cost by reducing the number of parts. I was able to put the cable management system inside the gantry space with zero interference to the operations. The alterations to the y-axis cable management system has reduced the effective width to 33.75 inches. The y-axis stepper motor mounts will also be eventually replaced to further remove the width of the machine from 33.75" inches to 31.75". Thus, at the end of the y-axis modifications the machine will have a 9.3% improvement in space reduction (3.25"/35.00").

Before

After

Analysis

Physics the Honey badger of the world. It keeps going!

Thread Tolerances

Setup

Video

Screw

Screw Dimensions |

#1 |

#2 |

#3 |

#4 |

|---|---|---|---|---|

l to 1st Thread |

0.348" |

0.3385" |

0.3455" |

0.3385" |

Total Length |

0.3855" |

0.3845" |

0.3900" |

0.3845" |

Clearance height \(\delta \)

Screw |

#1 |

#2 |

#3 |

#4 |

|---|---|---|---|---|

Loc. A |

0.0015 |

0.0004 |

0.0010 |

0.0005 |

Loc. B |

0.0020 |

0.0000 |

0.0020 |

0.0015 |

Loc. C |

0.0030 |

0.0020 |

0.0030 |

0.0030 |

Loc. D |

0.0010 |

0.0020 |

0.0020 |

0.0010 |

...

Topic A

Topic B

Discussion

...

→ ...

References

DARE2MAKE CHALLENGE

Find Your Passion

Invest in Education & Growth

Make Something Amazing

Schedule

- Overview Meche PE

- Product Dev. Process

- Product Take Apart

- I - Principles

- → Foundation

- → A - Basic Engineering Practices

- → B - Engineering Science and Mechanics

- → C - Material Properties

- → D - Strength of Materials

- → E - Vibration

- II - Applications

- → A - Mechanical Components

- → B - Joints and Fasteners

- → C - Supportive Knowledge

- III - Holistic Knowledge

- → A - Heat Transfer

- → B - Fluid Dynamics

- → C - Controls

- → D - Thermodynamics

- → E - Electronics

- IIII - Precision Machine

- → A - Error Apportionment

- → B - Metrology